3D Printing: The Dawn of A New Tech Age

3D printing technology has come a long way in recent years, and it is now possible to create complex 3D objects using a variety of materials! Just a handful of years earlier, it would have been impossible even to imagine a phenomenon like this! This technology has a wide range of applications, from creating medical implants to printing food. One of the most exciting aspects of 3D printing is its potential to absolutely revolutionize the manufacturing process.

Here’s a warm welcome if you’re new to the blog, and a welcome back if you’re one of our regulars! In our last blog, we discussed the exciting upcoming event of the Decentraland Metaverse Fashion Week for 2023! Haven’t read it yet? Click below!

Coming back to today’s discussion, with 3D printing technology, companies can create prototypes and products much faster and more cheaply than with traditional manufacturing methods. This could lead to a reduction in the overall cost of manufacturing, as well as a shorter lead time from design to final product.

3D printing is also becoming more accessible to consumers. Home 3D printers are becoming more affordable, and there are now a number of online services that allow anyone to upload a 3D design and have it printed. This technology is still in its early stages, but it has the potential to change the way we create and consume products.

How Does 3D Printing Work?

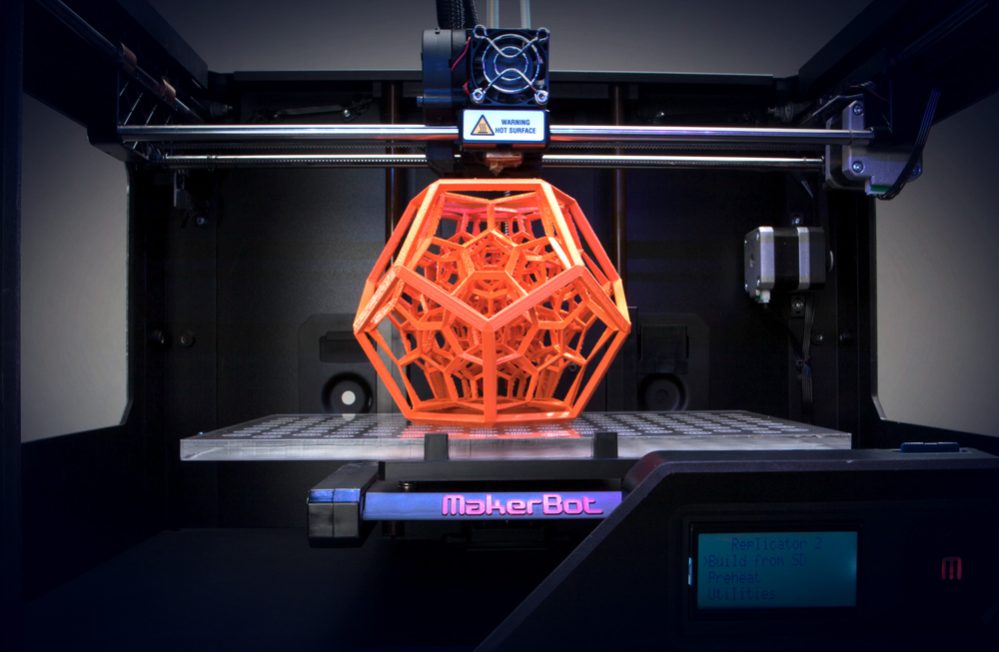

3D printing is a process of making three-dimensional solid objects from a digital file. A 3D-printed object is created using additive processes, where successive layers of material are laid down in different shapes.

It creates an object from bottom to top according to the form that has been fed into it, creating layers. It uses plastic-based materials- basically those materials which have the capacity to become molten under heat and subsequently solidify again.

Duration

The printing time depends on a number of factors, including the size of the part and the settings used for printing. 3D printing can take anything from a few minutes to several hours or days.

It’s typically fast, with low fixed setup costs, and can create more complex geometries than ‘traditional’ technologies, with a list of materials. It is used extensively in the engineering industry, particularly for prototyping and creating lightweight geometries.

The Process

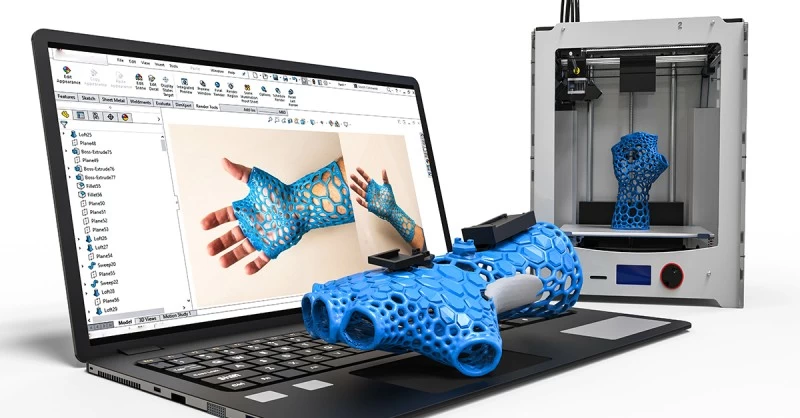

3D Softwares

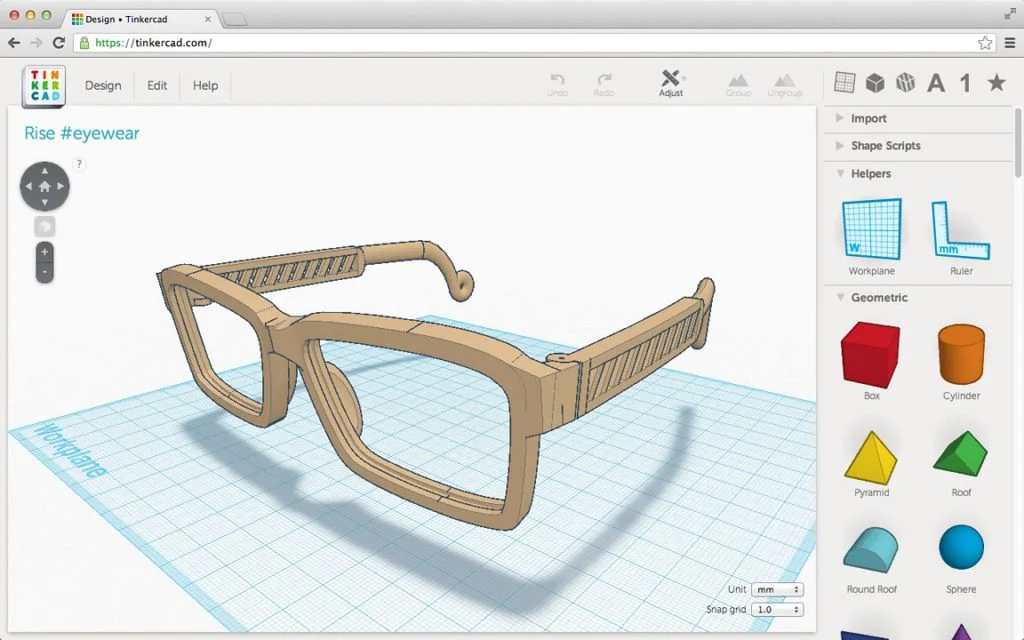

There are several software programs accessible. From commercial to open source. CAD is a widely used software to create the 3D form of the object that is to be printed.

Now that you have a printable file, you may prepare it for your 3D printer. This is known as slicing.

Slicing: Transferring a printable file to a 3D printer

Slicing is the process of dividing a 3D object into hundreds or thousands of layers using slicing software.

You can further feed the file into the 3D printer and attach the required material in it’s place.

Fashion & 3D Printing: The Relation

Luxury fashion firms have begun to include 3D printing in their creative process. Look through Balenciaga’s Autumn Winter 2018 collection. It’s astonishing to learn that the clothing was made from 3D-printed parts. The precise measurements of each model were recorded and entered into the computer to be produced according to the fitting specifications.

We’ve walked through the entire process of 3D printing, and needless to say, it is a world that has so much to explore- whether in fashion or other fields. Check out our other articles below and until then look out for our next one!

Hey there! 👋 Thanks for reading. Join our newsletter to be the first one to get updates and more and also check out our other topics that can interest you!

**Check your Promotion Tab

- 5 Best CLO 3D AlternativesTop 5 CLO3D Alternatives in 2024 In this article we will be introducing you to the top 5 CLO3D alternatives… Continue reading 5 Best CLO 3D Alternatives

- CLO3D and Blender Course Guide | Learn 3D FashionDive into the world of 3D design with our essential guide to CLO 3D and Blender courses. Perfect for artists and designers at any level, this guide covers everything you need to know to start creating stunning 3D models and animations.

- CLO 3D for Beginners course guideGet started with the Free clo3d beginners course guide. Understand how 3D Fashion is shaping the future of fashion and start learning clo3d.

- Pattern Making with CLO 3D | A Beginners GuidePattern Making with CLO 3D | A Beginners Guide Introduction Welcome to the fascinating world of digital fashion design, where… Continue reading Pattern Making with CLO 3D | A Beginners Guide

- CLO vs. Browzwear (and the Rest!) – What is best for beginners?Fashion Tech Showdown: CLO vs. Browzwear (and the Rest!) – Who is best for beginners? Tired of flat sketches and… Continue reading CLO vs. Browzwear (and the Rest!) – What is best for beginners?

- Master CLO 3D Fashion Design: Enroll in Our Live Classes Today!Master CLO 3D Fashion Design: Enroll in Our Live Classes Today!